Home > Armoured Cable > high voltage cable >

High Voltage Cable

High voltage cables suitable for a variety of applications, from powering homes and businesses to large-scale industrial operations. Knowing how these cables work and understanding their various components is essential for anyone looking to install or maintain them.

What Is Underground High Voltage Cable

High voltage power cables is a type of electrical wiring that is designed to carry large amounts of power from one point to another. It typically consists of several insulated conductors contained within a protective sheath. Underground high voltage cables are specifically designed to be buried beneath the ground. These underground high voltage cable differ from those used above ground in several ways, including their insulation and the number of conductors. The outer protective covering is typically composed of a non-conductive material such as polyethylene or lead sheathing, which helps protect against corrosion and other damage caused by the elements. The insulation between the individual conductors is also thicker than what would be found in an above ground cable, providing better protection against electrical shorts and protecting against environmental hazards like water infiltration. Other benefits of underground high voltage cable include improved safety for personnel working near them, reduced fire hazard in areas where large amounts of electricity are being moved, and improved reliability due to fewer problems with weather-related interruptions or fluctuations in power over long distances.

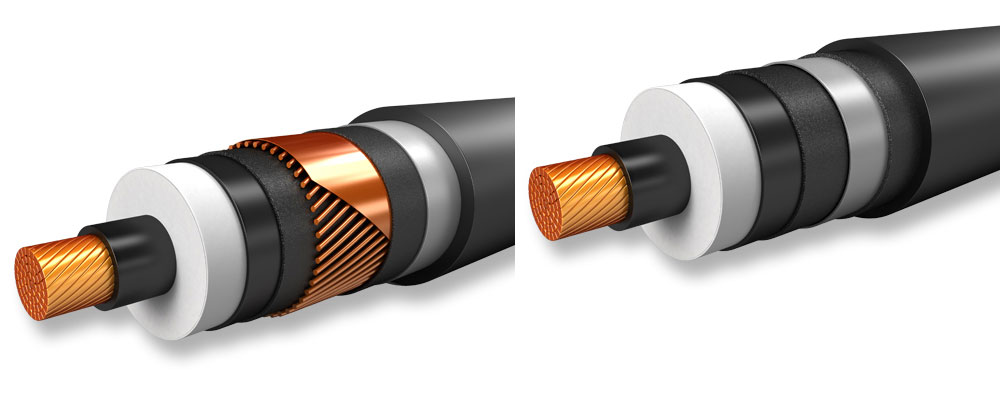

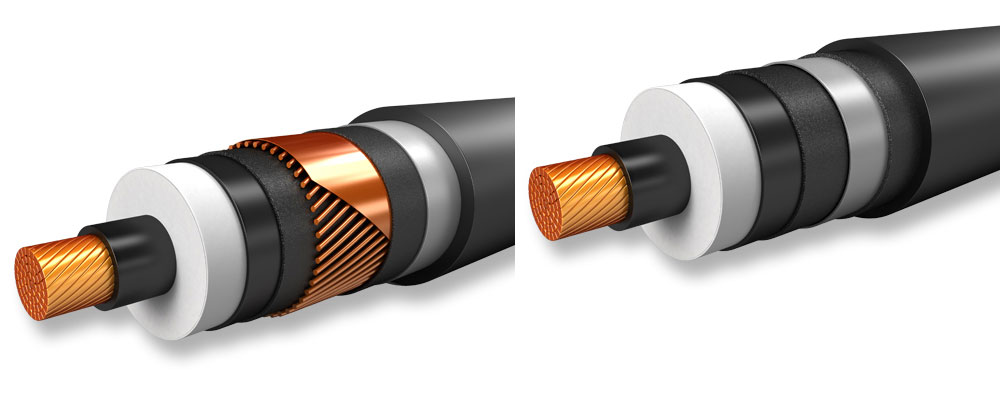

High Voltage Cable Construction

The construction of hv cable begins with the selection of materials that are suitable for use with high voltages. The insulation material is typically made out of rubber or plastic, while the conductor is usually made out of copper or aluminum. Specialized insulation materials may also be used in order to provide additional protection against electrical surges and corrosion. Additionally, a protective coating may be applied over the exposed metal parts in order to further reduce any risk of damage or shorts. Once the insulation has been selected, it must then be connected to the conductor using specialized tools and equipment such as crimping machines. After the connection has been completed, the cable is then tested in order to ensure that it meets all applicable safety standards. Finally, protective shielding may be added around the cable in order to provide additional protection from moisture and other external elements. high voltage electrical cables are an important part of any electrical network and require careful construction in order to ensure safety and reliability. The selection of appropriate materials, proper installation techniques, and rigorous testing can help ensure that these cables will perform optimally for many years to come.

Types Of High Voltage Cables

high voltage electrical cable is a type of electrical conductor used to carry large amounts of current from one point to another. It is usually made of copper or aluminum and is insulated with rubber, plastic, metal or paper. HV cables are typically used in industrial applications where large currents need to be transmitted over long distances. There are several types of high voltage power cables available on the market today, each designed for a specific application. For example, an XLPE (cross-linked polyethylene) high voltage power cables is used to transmit electricity at higher voltages than standard cables. This type of cable has a dielectric strength that can range from 1kV/mm up to 36 kV/mm and can handle currents up to 1000A. An oil-filled power cable is another type of high voltage cable that is designed for use in areas with extreme temperatures or vibration levels. This type of cable also has a higher dielectric strength and can handle up to 45kV/mm and 2000A of current. The construction of high voltage cables involves using multiple layers of insulation material in order to reduce the risk of electric shock and minimize the risks associated with electric arcs. The outer layer must be able to withstand the environment it will be exposed to, such as weathering, sunlight, abrasion and water damage. The inner layer must protect the conductor from any kind of physical damage due to movement or installation errors.

76/132kv High Voltage Cable Size Chart

|

76/132kv High Voltage Cable Constructional & Electrical Data |

|

Conductor |

Insulation |

Metallic Screen |

Outer Jacket |

|

Nominal Area |

Max. DC Resis- tance at 20 °C |

Max. AC Resis- tance at 90 °C |

Nominal Thickness of Insulation Layers |

Electro- static Capaci- tance |

Nominal Area of Copper Wires |

Short Circuit Capacity (1 Sec.)(1) |

Nominal Thick- ness |

Approx. Overall Diameter |

Approx. Overall Weight |

|

Cond. Screen |

XLPE |

Ins. Screen |

|

mm2 |

Ω / km |

Ω / km |

mm |

mm |

mm |

μF / km |

mm2 |

kA |

mm |

mm |

kg / m |

|

300 R |

0.0601 |

0.0785 |

1.2 |

21.6 |

1.75 |

0.134 |

280 |

40 |

3.95 |

85.5 |

9.99 |

|

400 R |

0.047 |

0.0624 |

1.2 |

21.6 |

1.75 |

0.143 |

280 |

40 |

3.95 |

88.1 |

10.99 |

|

500 R |

0.0366 |

0.0499 |

1.2 |

21.6 |

1.75 |

0.155 |

280 |

40 |

3.95 |

91.5 |

12.33 |

|

630 R |

0.0283 |

0.0402 |

1.2 |

21.6 |

1.75 |

0.167 |

280 |

40 |

3.95 |

95 |

13.84 |

|

800 R |

0.0221 |

0.0333 |

1.2 |

21.6 |

1.75 |

0.18 |

280 |

40 |

3.95 |

99 |

15.88 |

|

1000 S |

0.0176 |

0.0238 |

1.5 |

21.6 |

1.75 |

0.21 |

280 |

40 |

3.95 |

107.7 |

18.54 |

|

1200 S |

0.0151 |

0.0209 |

1.5 |

21.6 |

1.75 |

0.223 |

280 |

40 |

3.95 |

111.7 |

20.74 |

|

1400 S |

0.0129 |

0.0183 |

1.5 |

21.6 |

1.75 |

0.229 |

280 |

40 |

3.95 |

113.7 |

22.76 |

|

1600 S |

0.0113 |

0.0166 |

1.5 |

21.6 |

1.75 |

0.243 |

280 |

40 |

3.95 |

117.7 |

24.58 |

|

2000 S |

0.009 |

0.0141 |

1.5 |

21.6 |

1.75 |

0.259 |

280 |

40 |

3.95 |

122.7 |

28.37 |

|

2500 S |

0.0072 |

0.0122 |

1.5 |

21.6 |

1.75 |

0.285 |

280 |

40 |

3.95 |

130.7 |

34.1 |

High Voltage Cable Price List

High voltage cables are designed to transmit large amounts of electrical energy over long distances with minimal losses. Prices for high voltage cables vary depending on the type of cable, its construction, and the voltage it is designed to carry. High voltage cable price is based on the size of the conductor, the insulation used, application and specifications. Larger cables tend to cost more as they require more insulation material and often have higher ratings than smaller ones. High voltage cables price also depends on their intended application. Cables used for transmission lines will normally be more expensive than those used for distribution lines due to their higher specifications. Additionally, if the cable needs to be laid in difficult terrain or an area with high seismic activity, that can significantly increase its price tag. Manufacturer also plays an important role in determining a cable's price. Some manufacturers specialize in specific types of high voltage cables while others offer a wide range of products at different price points. It's important to research each manufacturer before making a purchase decision as prices can vary significantly between manufacturers even when comparing similar products. Finally, bulk discounts may apply when purchasing large quantities of hv cables from some suppliers so it's worth checking to see if there are any special deals available before making a purchase.

Conclusion

In conclusion, high voltage cable is a necessary component in many electrical systems. It is important to understand the different types and construction of these cables to ensure that they are installed safely and meet their desired purpose. Additionally, it is important to consider the pricing for these cables when determining which option works best for your project. With this knowledge, you can make an informed decision when selecting a high voltage cable for your needs.